Low-volume injection molding involves creating smaller batches of products using injection molding techniques. This method is particularly useful for manufacturers who need to create small quantities of products quickly and efficiently. It also allows manufacturers to test new product designs without committing to high-volume production runs.

One company that has embraced low-volume injection molding is Star Machining Technology Co., Limited. Star Machining Technology Co., Limited specializes in precision-machined components and molds developing & manufacturing from the aerospace industry to custom projects. The company has invested heavily in advanced equipment and technology to ensure that its products meet the highest standards of quality and precision.

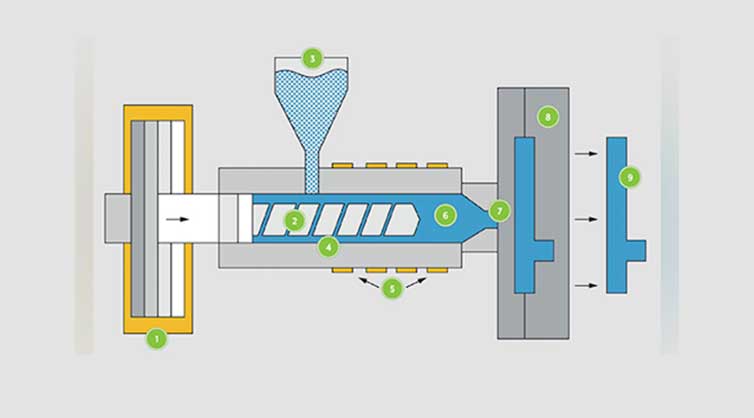

Star Machining Technology Co., Limited's low-volume injection molding process begins with a detailed design specification for the product. The company's engineers use advanced software to create a 3D model of the product, which is then used to create a mold. Once the mold is created, a small batch of the product is produced using injection molding techniques. The product is then tested and inspected to ensure that it meets the customer's specifications.

One of the main advantages of low-volume injection molding is its speed. Instead of waiting weeks or even months for a product to be produced, manufacturers can now have a small batch of products produced in a matter of days. This speed is particularly beneficial for manufacturers who need to respond rapidly to changing market conditions.

Another advantage of low-volume injection molding is its flexibility. By creating small batches of products, manufacturers can test new product designs without committing to high-volume production runs. This means that manufacturers can experiment with new products and make adjustments based on customer feedback before committing to large-scale production.

Star Machining Technology Co., Limited's low-volume injection molding process also offers excellent precision and consistency. By using advanced equipment and technology, the company is able to produce parts that meet very tight tolerances. This precision is particularly important for products that need to function correctly and consistently.

Overall, low-volume injection molding is a highly effective method for manufacturers who need to produce small quantities of products quickly and efficiently. Star Machining Technology Co., Limited has embraced this method and is leveraging its numerous benefits to help its customers stay ahead of the competition. With its focus on advanced technology and precision, Star Machining Technology Co., Limited is poised to continue to grow and expand its capabilities in the years ahead.