Injection molded rubber parts are critical components used in several industries, including automotive, healthcare, aerospace, and consumer products. These parts offer versatility, durability, and excellent performance, making them indispensable in various applications.

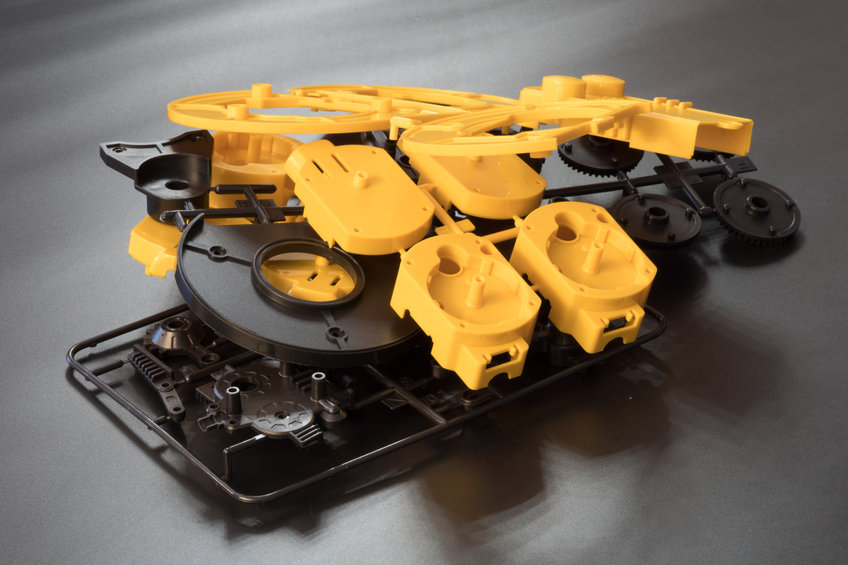

The process of injection molding rubber parts is complex but reliable. The first step is to create a mold with a cavity in the desired shape and size of the end product. The molten rubber is then injected into the mold cavity and allowed to cure. The mold is then opened, and the finished part is ejected.

Injection molding rubber parts offer many advantages. One significant advantage is that this process can create intricate and precise designs. This is because the mold cavity can be designed to create complex shapes and asymmetrical parts with high precision.

Another advantage of injection molding rubber parts is that it can produce parts with uniform thicknesses. This is important in applications where dimensional accuracy is critical, such as gaskets, seals, and O-rings.

Injection molded rubber parts also offer excellent chemical resistance, high tensile strength, and flexibility. They can withstand high temperatures and pressures, making them ideal for use in harsh environments. Additionally, they can be produced in various colors, textures, and hardness levels, providing many options for customization.

At Allflex Packaging Products, we specialize in injection molded rubber parts production. We utilize advanced injection molding machines with high precision to produce quality rubber parts that meet your exact specifications. Our experienced team of engineers and designers work closely with our clients to ensure that the final product meets their unique needs.

We understand that time is of the essence in the manufacturing industry, and that's why we are committed to delivering our clients' orders in a timely and efficient manner. Our state-of-the-art manufacturing process ensures that we consistently produce high-quality injection molded rubber parts that meet our clients' expectations.

In conclusion, injection molding is a reliable and versatile process that can produce high-performance rubber parts for a wide range of applications. Allflex Packaging Products is a trusted partner in the injection molding industry, where we specialize in the production of injection molded rubber parts. With our advanced injection molding techniques, experienced team, and commitment to our clients' satisfaction, we are confident that we can meet all your injection molding needs. Contact us today to learn more about our services.